Industrial IoT solution

that detects the "unusual behavior" of equipment

Don’t you entrust equipment maintenance

solely to operator rounds?

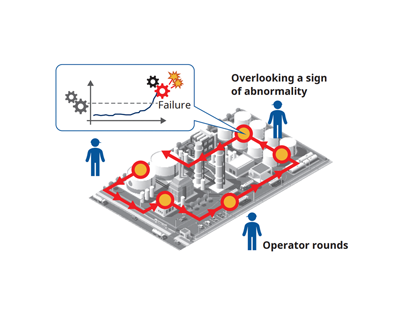

There is a limit to monitoring “everything” about the equipment deployed across a large plant.

In addition, most of the equipment data measured during the operator rounds is recorded on paper manually, and the measured data is not fully utilized for equipment maintenance, except for some critical equipment.

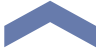

Sushi Sensor is a wireless solution for industrial IoT, including sensors such as vibration, temperature, and pressure to monitor equipment conditions continuously. By introducing Sushi Sensor, it is possible to monitor the equipment deployed in a wide plant from a remote location efficiently.

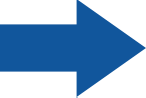

Case 1:

Efficiency of equipment maintenance

Due to the aging of equipment and the retirement of skilled operators, it is required to carry out efficient equipment maintenance without relying on human-dependent manual operation.

By introducing Sushi Sensor, the signs of equipment "unusual behavior" are detected remotely, so that the frequency of operator rounds can be reduced and the equipment that requires closer monitoring is automatically identified in the plant.

Before installation

Much number of man-hour of the operator rounds is used to confirm that "there is no difference from the equipment working as usual".

After installation

A simple diagnosis which detects signs of abnormalities is performed by Sushi Sensor, and then the operator carries out a detailed diagnosis of equipment with those signs of abnormality to define the type and cause of failure.

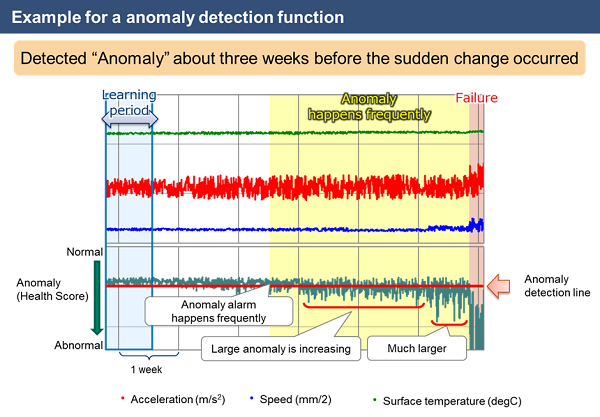

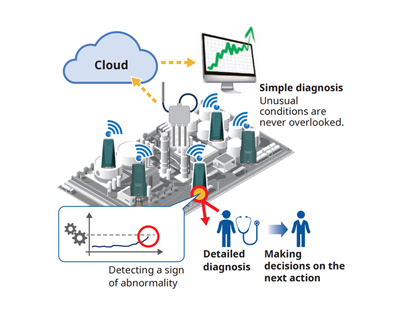

The following figure is a graph of a chemical company measuring the vibration value of a pump by using a wireless vibration sensor.

An abnormal rise in the acceleration of the pump was observed, so when the rolling bearing of the pump was disassembled and inspected, the failure of the ball bearing was found. This is an example in which it was confirmed that even if the measurement is performed once an hour, the signs of abnormality can be sufficiently detected by monitoring the tendency.

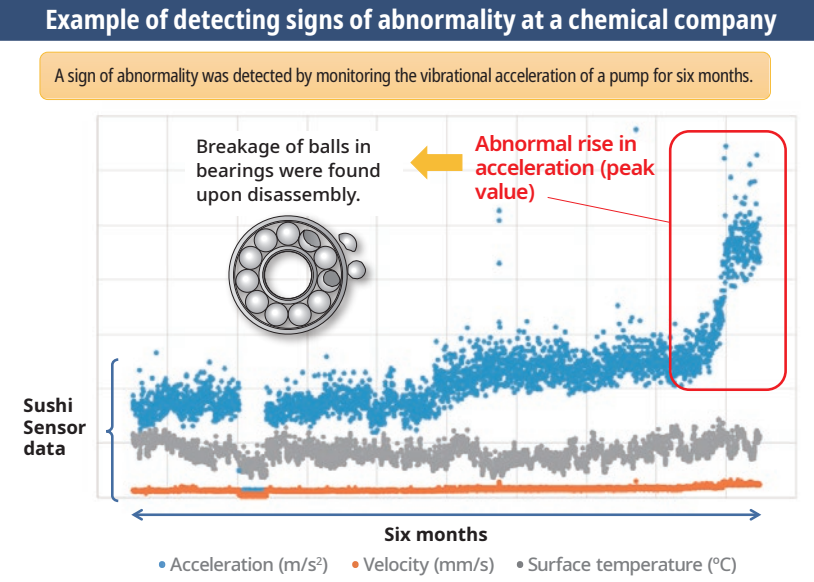

Case 2:

AI Anomaly Detection

Do you want to analysis the equipment data appropriately, or want to leave the simple diagnosis to AI?

By combining the data logging software GA10 and Sushi Sensor, AI will automatically notify you of any signs of equipment abnormality as "Anomaly". It is possible to automatically identify the equipment that requires detailed diagnosis in a plant with a lot of equipment.

The following figure shows an example of AI detecting "Anomaly" about 3 weeks before a sudden change in vibration value occurs. By using the email function of GA10, it is possible to notify by sending an email under the conditions of alarm occurrence, specified cycle, specified time, or communication error.