Have your heat treatment furnaces gone digital?

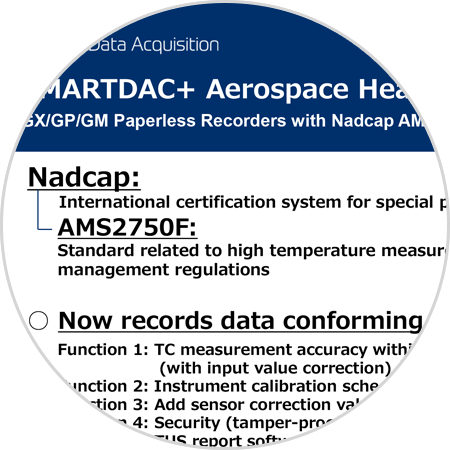

* Nadcap/AMS2750F requires digitalization of all recorders and controllers by June 2022.

* Nadcap/AMS2750F requires digitalization of all recorders and controllers by June 2022.

* Nadcap/AMS2750F requires digitalization of all recorders and controllers by June 2022.

* Nadcap/AMS2750F requires digitalization of all recorders and controllers by June 2022.

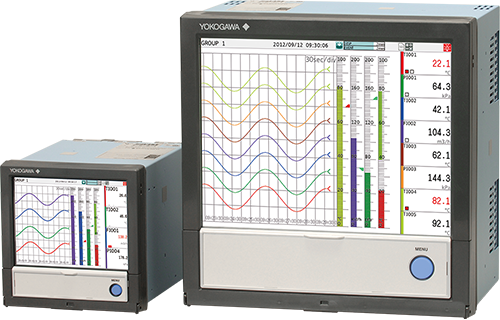

YOKOGAWA's recorders (SMARTDAC+) and controllers (UTAdvanced) meet the demands of Nadcap/AMS2750 and IATF16949/CQI-9.

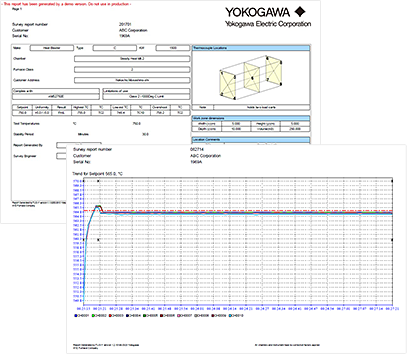

Paperless recorders for batch process and Temperature Uniformity Survey (TUS) applications

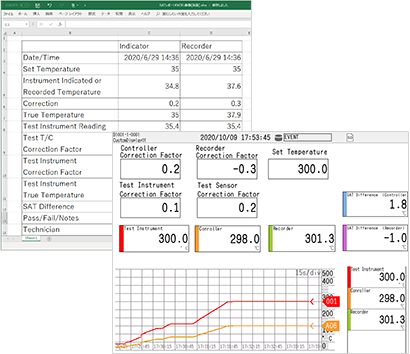

Accuracy within ±1.0°F or ±0.6°C(or ±0.5°F or ±0.3°C for types K, N, J, and T)

Digital indicating controllers for precise thermal asset operation

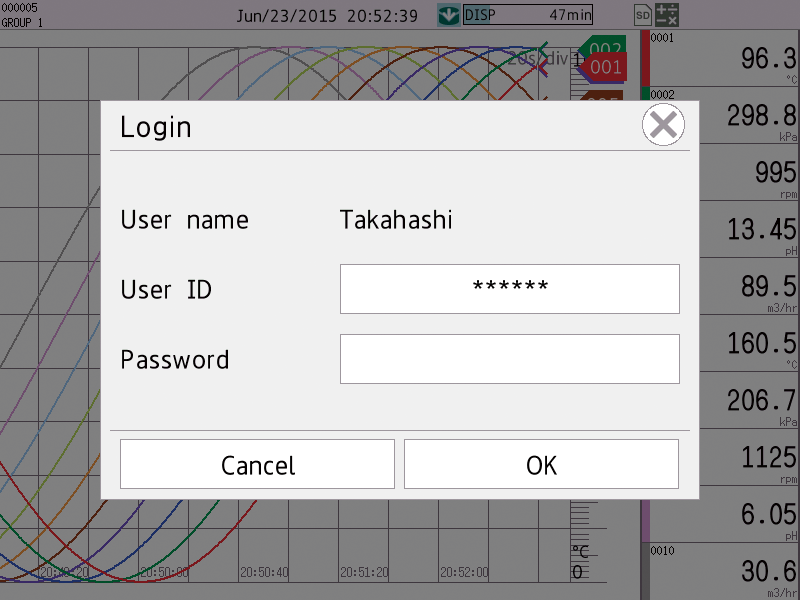

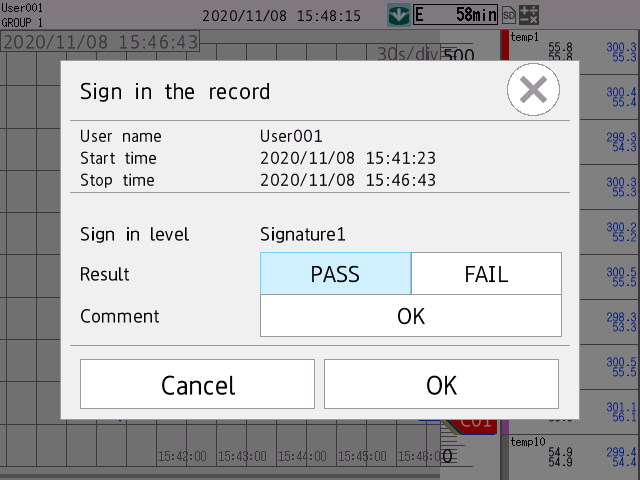

Login password prevents unauthorized operation

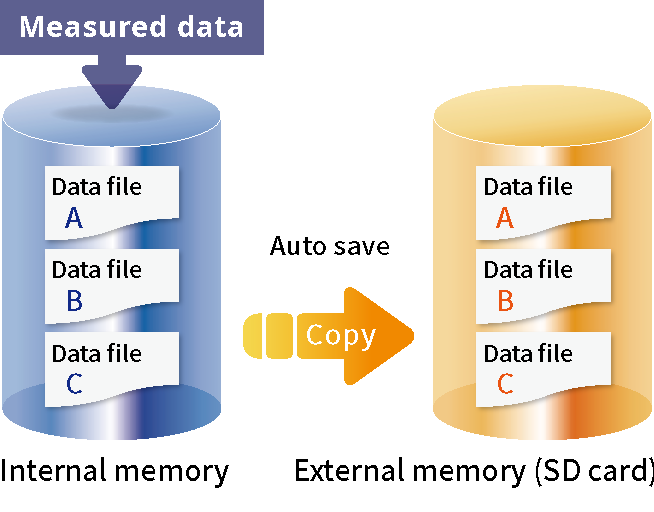

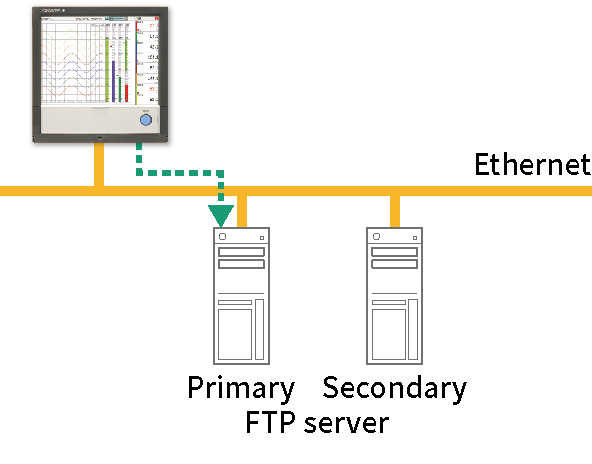

Measured data is saved in secure tamper-proof data files

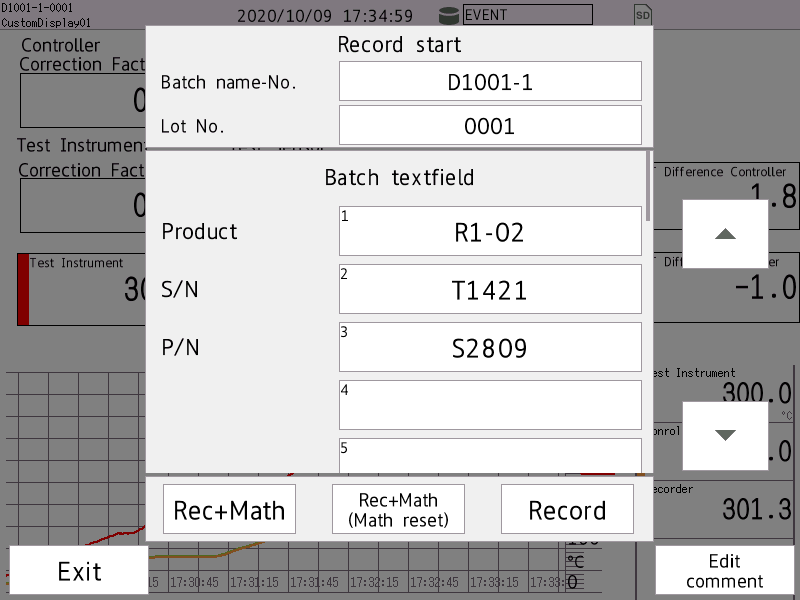

Batch information can be recorded along with the measured data

Easily create TUS reports from recorded data files on your PC

Automate SAT report generation

Paperless recorders with Nadcap/AMS2750F support

See how SMARTDAC+ supports standards.

Paperless recorders with IATF16949/CQI-9

See the benefits of instruments supporting IATF16949/CQI-9.